Management software and AI for the Manufacturing industry

Production optimisation, up to 30% increase in output

Simplified traceability up to 40% more efficient

Quality control , 25% reduction in defects

Predictive Maintenance up to 35% reduction in downtime

Production optimisation

Thanks to our suite of advanced functions, we can help you optimise your production, reducing costs and increasing efficiency by up to 30%.

Improved traceability

Our product and batch tracking system guarantees complete traceability, offering up to 40% efficiency gains in your tracking and stock management processes.

Precise Data Acquisition

By collecting and analysing data from each PLC, we improve the accuracy of your decision-making process by up to 20%, ensuring greater responsiveness and better planning.

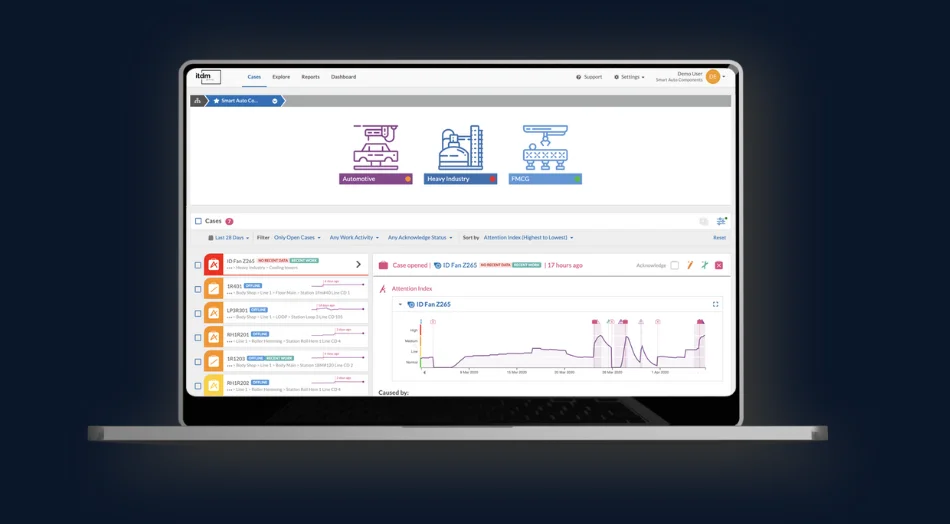

Predictive Maintenance

Our predictive maintenance solution uses advanced data analysis to anticipate breakdowns and reduce unscheduled downtime by up to 35%, optimising the availability of your equipment.

Advanced quality control

Thanks to our advanced quality control software, you can reduce production defects by up to 25%, ensuring consistent, reliable product quality.

Integrated Resource Management

Our platform enables holistic resource management, reducing waste by up to 30% and optimising the use of raw materials, labour and equipment, all contributing to greater profitability.

Our made-to-measure creations

One Network Three

Libeer mea dictas eirmod scripserit, iisque vivendum eu usu.

Find the best plan

for your needs

Basic Plan

- Affert volumus legend

- Mel detracto atomorum ne

- Eripuit minimum probatus ei

- Vix ex natum iracundia

Standard Plan

- Affert volumus legend

- Mel detracto atomorum ne

- Eripuit minimum probatus ei

- Vix ex natum iracundia

Premium Plan

- Affert volumus legend

- Mel detracto atomorum ne

- Eripuit minimum probatus ei

- Vix ex natum iracundia

Creation of customised production management software for the manufacturing industry

Customer issue :

Solutions :

Results :

Data Centralisation: Integration of all production, order and stock information on a single platform for simplified management and real-time access to crucial data.

Process automation: Implementation of automated functions for order tracking, stock management and resource planning, reducing manual administrative tasks and minimising the risk of errors.

Real-time tracking:Development of real-time tracking tools to monitor stock levels, order status and production performance, enabling rapid, informed decision-making.

Advanced planning:Creation of advanced planning tools enabling managers to view and manage production schedules effectively, taking into account production capacity and delivery times.

Improved operational efficiency: 50% reduction in the time spent managing stocks and orders thanks to automated processes.

Reduced errors: 40% reduction in errors associated with manual stock and order management, ensuring greater precision in resource management.

Increased productivity: 35% increase in the productivity of production teams by reducing repetitive administrative tasks and optimising the use of resources.

Resource optimisation: 45% improvement in resource planning, enabling more efficient use of production capacity and better management of delivery times.

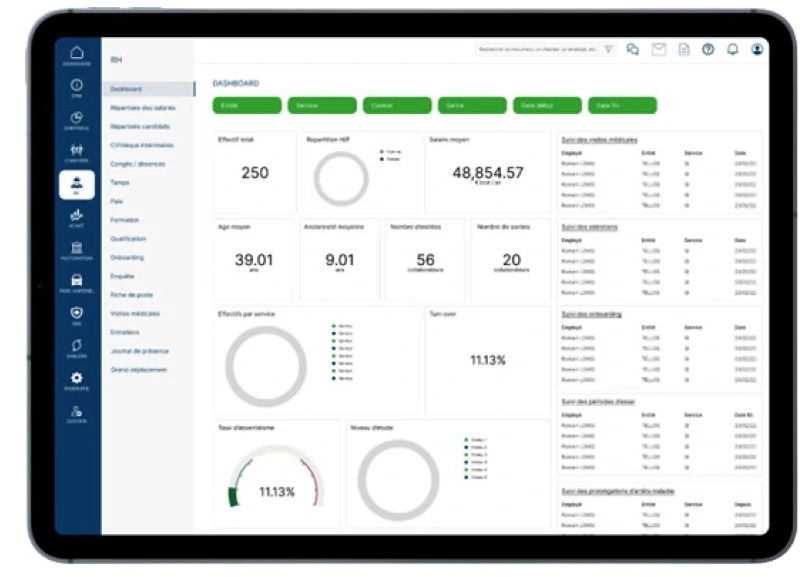

Creation of bespoke ERP software internal management software Tellos Group

Customer issue :

Solutions :

Results :

Centralisation of data: integration of all employee holiday information into a single platform for simplified management and easy access to data.

Automated functions for requesting, approving and monitoring leave, reducing manual administrative tasks and the risk of errors.

Creation of a leave tracking system and individual employee files for efficient management of leave history and remaining entitlements.

Development of advanced planning tools enabling managers to view and manage leave schedules efficiently, taking into account the team's availability and needs.

- 60% reduction in time spent on holiday management thanks to automated processes.

-50% fewer errors associated with manual holiday management, which contributes to more accurate monitoring of holiday entitlements and balances.

Increased HR team productivity by over 30% by reducing repetitive administrative tasks and freeing up time for higher added-value activities.